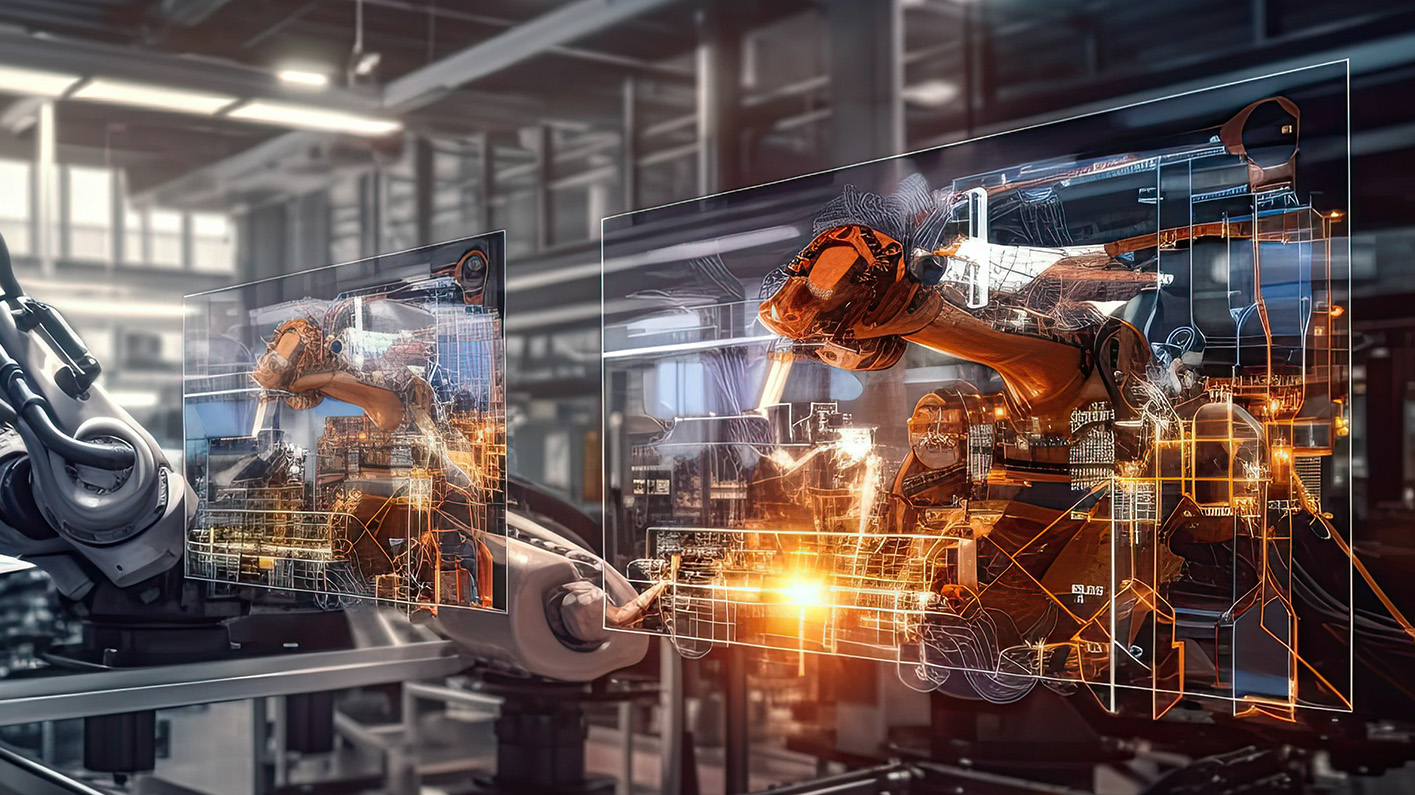

One of the most important technologies in manufacturing today is digital twins, virtual replicas of physical assets, processes, or systems that can be used to monitor, analyze, and optimize performance. In this article, we explore the rise of digital twins in supply chain management, discuss their benefits and challenges, and examine how they can be implemented. We also look at the future of digital twins and how they are likely to continue to transform manufacturing.

The benefits of digital twins in supply chain management

Digital twins are not a new concept — their roots trace back several decades. However, advances in technology have finally made them a reality, enabling unprecedented insights into supply chains. These virtual representations accurately reflect their physical counterparts, allowing for close monitoring, analysis, and optimization.

With the help of sensors, IoT devices, and artificial intelligence (AI), digital twins leverage real-time data to optimize supply chain management strategies, leading to increased efficiency, cost reduction, and better decision-making across areas including those below:

Tracking

Digital twins can track the location and condition of goods, ensuring that products reach their destinations in optimal condition. By monitoring production processes, you can pinpoint bottlenecks, optimize workflows, and minimize downtime. Also, digital twins help in managing inventory levels, reducing waste, and ensuring that the right products are available when and where they are needed.

Testing

The real-time data provided by digital twins helps make informed decisions, ensuring that supply chains remain agile and responsive to changing market demands. By simulating different scenarios and testing various strategies, you can identify the most efficient and cost-effective ways to operate. As technology continues to evolve, the potential of digital twins will only grow, promising even greater benefits.

Prevention

Digital twin virtual replicas of physical assets and processes provide proactive maintenance capabilities, enabling you to uncover and address potential issues before they disrupt the supply chain. This not only minimizes downtime and maximizes productivity but also significantly reduces maintenance costs.

Implementing digital twins

To successfully implement digital twins, there are several key steps that need to be taken.

- Create a digital twin of the physical assets involved in the supply chain. This can be done by collecting data about the assets, such as their dimensions, weight, and location. This data can then be used to create a virtual model of the asset that can be used for monitoring and analysis.

- Connect digital twins to real-time data sources. This allows them to be updated with the latest information about the physical assets, which will enable more accurate monitoring and analysis. Real-time data sources can include sensors, IoT devices, and enterprise resource planning (ERP) systems.

- Analyze the data from digital twins. This enables you to identify trends and patterns in the data, which can then be used to make informed decisions about the supply chain. Data analytics can be used to analyze things like production, inventory, and logistics data.

- Use insights from digital twins to make informed decisions about the supply chain. This can include decisions about production schedules, inventory levels, and logistics. By using insights from digital twins, you can improve the efficiency and effectiveness of your supply chain.

Challenges and limitations of digital twins

While digital twins offer many benefits for supply chain management, it is important to acknowledge the challenges and limitations associated with their implementation:

Data accuracy and consistency

Digital twins rely on real-time data from various sources, including sensors, IoT devices, GPS satellites, middleware technology, and enterprise resource planning (ERP) systems. Ensuring the accuracy and consistency of this data is paramount for reliable decision-making. Data discrepancies can lead to incorrect insights and suboptimal decision-making, hindering supply chain efficiency.

Computational complexity

Digital twins can generate massive amounts of data, especially in large-scale supply chain networks. Processing and analyzing this data in real-time requires substantial computational power and sophisticated algorithms. Computational complexity increases with the number of variables and the level of detail required, straining IT resources and slowing down decision-making processes.

Security and privacy

Digital twins involve the collection and storage of sensitive data, including production processes, inventory levels, and customer information. Ensuring robust security measures to protect this data from unauthorized access, breaches, and cyber threats is crucial. Additionally, privacy concerns must be addressed, particularly when dealing with personal information, to comply with data protection regulations.

Integration with existing systems

Integrating digital twins with existing supply chain systems can be challenging. Legacy systems may not be compatible with the data formats and communication protocols required by digital twins. This can hinder the seamless flow of information and impede their effective utilization across the entire supply chain. Working with an experienced consulting partner can ensure a successful implementation of digital twin and IoT capabilities.

Digital twins in Oracle IoT Intelligent Applications

Digital twin modeling is part of Oracle Internet of Things (IoT) Intelligent Applications, helping you simulate supply chains, run what-if analyses, and predict potential disruptions. By combining data from digital twin IoT devices with AI-generated insights, you can make more informed decisions and optimize operations in real time.

Digital twins can also help you reduce environmental impact by optimizing resource utilization and minimizing waste. This is becoming increasingly important as consumers demand more sustainable products and services. The future of digital twins in supply chain management is full of potential, and companies of all sizes will be able to use digital twins to create more efficient, resilient, and sustainable supply chains.

To learn more about digital twins and how to effectively implement smarter, more resilient supply chains within your supply chain management, please contact us today!